Before starting your own brand, look at the pros and cons of domestic vs. international manufacturers for body care brands. This decision is no mere coin toss; it’s a strategic move fraught with complexities and nuances.

Understanding the right manufacturing strategy is crucial for any body care brand aiming to thrive in a saturated and ever-evolving market. It’s not just about where your products are made; it’s about aligning your brand’s ethos, sustainability practices, cost considerations, and market reach with the manufacturer that best fits these criteria. The choice between domestic and international production involves many factors, including but not limited to cost efficiency, quality control, supply chain logistics, and ethical considerations.

On the one hand, domestic manufacturing could be synonymous with higher quality, faster turnaround times, and the appeal of supporting local economies. On the other hand, international manufacturing might offer cost benefits, access to unique materials, and scalability options that are not readily available locally. Each choice comes with its own advantages and challenges, and understanding these can make or break a body care brand’s success.

So, let’s dissect the merits and drawbacks of Domestic vs. International Manufacturers, helping you make an informed decision that benefits your brand and resonates with your values and vision. Whether you’re a budding entrepreneur in the body care realm or a seasoned player looking to re-evaluate your manufacturing strategy, this discussion promises to shed light on the critical aspects of this significant choice.

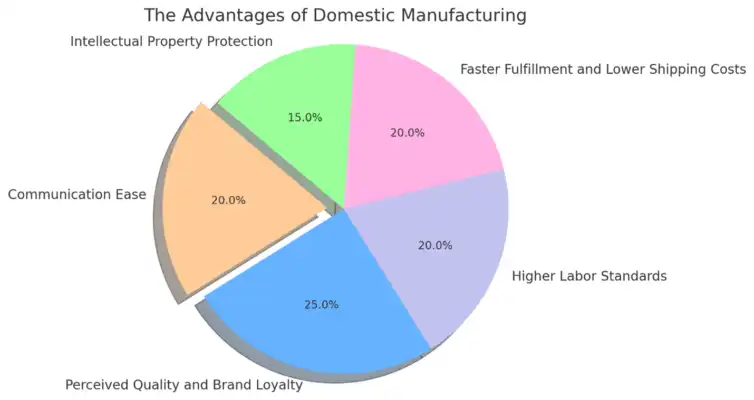

The Advantages of Domestic Manufacturing

For building a resilient and thriving body care brand, opting for domestic manufacturing comes with many undeniable benefits. These advantages bolster operational efficiency and significantly contribute to a brand’s reputation and customer satisfaction. Here’s a closer look at why bringing production closer to home can be a game-changer.

1. Communication Ease:

Consider being on a tight deadline to launch your new line of organic moisturizers, and every minute counts. Working with a domestic manufacturer means operating within the same time zone and speaking the same language, literally and figuratively.

This synergy allows for real-time problem-solving, swift decision-making, and a smoother production process. The absence of language barriers and time zone differences leads to fewer communication breakdowns, ensuring your product reaches the market precisely as you envisioned.

It’s not just about more effortless conversations; it’s about building a collaborative partnership where ideas flow seamlessly, and challenges are tackled promptly.

2. Perceived Quality and Brand Loyalty:

Now, let’s talk about perception and loyalty. There’s a compelling narrative around “Made in ZZZ” that resonates deeply with consumers. For instance, “Made in the USA” is not just a label; it’s a badge of quality and trust. This perception can justify higher price points, as consumers are often willing to pay more for products they believe are of superior quality.

Furthermore, this domestic association fosters a sense of pride and loyalty among customers, who are more likely to support and advocate for brands that contribute to their local economy. It’s a powerful story that can set your body care brand apart in a crowded marketplace.

3. Higher Labor Standards:

Choosing domestic manufacturing also means aligning your brand with higher labor standards. This ethical consideration goes a long way in enhancing your brand image and appeal, especially among socially conscious consumers.

Ensuring every product carries your brand’s name is a testament to fair labor practices and respect for workers’ rights. This commitment bolsters your company’s ethical stance and resonates with a growing market segment that values transparency and social responsibility.

It’s a clear message that you care, not just about the end product, but about every hand that touched it along the way.

4. Faster Fulfillment and Lower Shipping Costs:

The strategic advantage of geographical proximity cannot be overstated. By manufacturing domestically, you significantly reduce the distance between your products and your primary market. This closeness translates into faster fulfillment times and lower shipping costs, giving your brand a competitive edge in delivery speed and affordability.

Imagine being able to replenish stock at a moment’s notice or rapidly scaling production to meet unexpected demand. This agility is crucial in maintaining customer satisfaction and loyalty in an era where speed often equals success.

5. Intellectual Property Protection:

Lastly, the protection of your innovations and designs is paramount. Domestic manufacturing jurisdictions typically enforce intellectual property laws more vigorously, safeguarding your unique body care formulations and packaging designs from imitation. In a sector where innovation sets you apart, knowing that your intellectual property rights are robustly protected provides peace of mind and fosters a secure environment for creativity and growth.

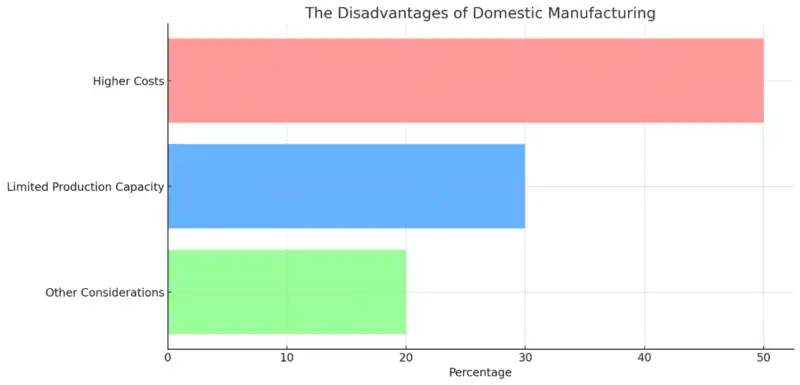

The Disadvantages of Domestic Manufacturing

Choosing a suitable manufacturing base is fraught with considerations, among which cost and capacity stand out. These factors can significantly influence a brand’s operational strategy and its competitiveness in the market.

1. Higher Costs:

One of the most cited drawbacks of domestic manufacturing is its higher operational costs. Labor standards, which are commendably higher in domestic settings, come with increased labor costs.

For instance, a body care brand based in the United States or Western Europe might grapple with manufacturing costs substantially higher than competitors who opt for production in countries with lower wage standards. This disparity can affect pricing strategies, potentially placing domestically produced items at a higher price than those manufactured abroad.

Consider the dilemma faced by a new entrant in the body care market, eager to highlight their commitment to ethical practices and local production. They discover that margins must be significantly reduced to maintain a competitive edge in pricing, making it a tough sell to cost-conscious consumers. This scenario illustrates why brands, especially startups with tight budgets, might lean towards international manufacturing as a cost-effective solution despite their preference for domestic production.

2. Limited Production Capacity:

Another critical factor is the issue of scalability and capacity. Domestic manufacturers, particularly those in highly regulated environments, may not be equipped to handle high-volume demands as efficiently as their international counterparts. This limitation can be a significant hurdle for body care brands looking to scale quickly in response to market demands or seasonal peaks.

Imagine a body care brand that experiences an unexpected surge in demand following a successful marketing campaign. The brand’s domestic manufacturer, constrained by limited production lines and the need to adhere to strict labor regulations, must meet the increased order volume, leading to stock shortages and potential revenue loss.

This scenario underscores why some brands might find international manufacturing options more appealing for their scalability and flexibility despite the benefits of domestic production.

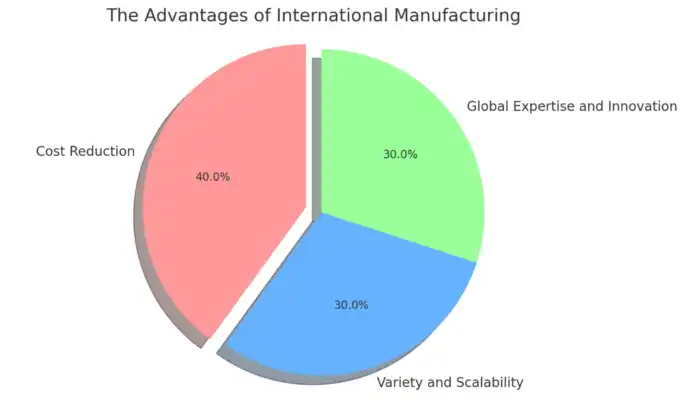

The Advantages of International Manufacturing

The global manufacturing landscape is rich with opportunities for body care brands looking to leverage the strengths of different markets. From cost reduction to accessing unparalleled expertise, the advantages of international manufacturing are compelling.

1. Cost Reduction:

Consider the economic dynamics of manufacturing in countries like China, Vietnam, or Bangladesh. These countries offer significantly lower labor and production costs due to their financial structures and market conditions. For instance, manufacturing a skincare line in China might cost substantially less than producing the same line domestically in the United States or Europe.

This cost efficiency allows brands to price their products more competitively in the global market, making high-quality body care accessible to a broader audience. The savings on production can also be reinvested into research and development, marketing, or expanding product lines, further enhancing the brand’s market position.

2. Variety and Scalability:

International manufacturing opens the door to vast manufacturing capabilities and materials that might need to be more readily available or cost-effective domestically. This variety allows for greater flexibility in product development and innovation.

Furthermore, the scalability that international manufacturers offer is a game-changer. Brands can quickly ramp up production to meet surges in demand without the constraints often faced by smaller domestic manufacturers. This scalability ensures that brands can grow without being hamstrung by production limitations, providing a clear pathway to meeting global demand efficiently.

3. Global Expertise and Innovation:

By partnering with international manufacturers, body care brands access a wealth of global expertise and technological advancements. Many international manufacturing hubs are at the forefront of technological innovation, offering state-of-the-art production methods to enhance product quality and efficiency significantly.

For example, South Korea is renowned for its advanced skincare technology and innovation. By manufacturing in such regions, brands can incorporate cutting-edge technologies and formulations into their products, setting new industry standards.

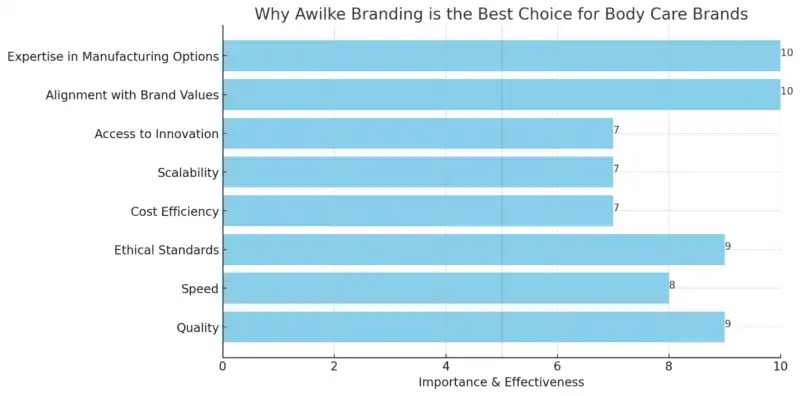

In bridging the gap between international and domestic needs, services like Awilke Branding emerge as vital partners for body care brands.

Awilke Branding positions itself as a conduit to the best of both worlds, offering brands the flexibility to navigate international and domestic manufacturing landscapes.

For brands in China or other parts of the world looking for an adept partner that understands the intricacies of global and local markets, Awilke Branding stands ready to deliver unparalleled service, ensuring that brands can leverage international manufacturing advantages while maintaining a strong domestic presence.

The Disadvantages of International Manufacturing

The global manufacturing arena offers vast opportunities but comes with unique hurdles. These challenges require strategic foresight and planning to navigate successfully.

1. Communication and Cultural Barriers:

The diversity of languages and cultures can lead to communication challenges and cultural misunderstandings. Misinterpretations can complicate business relationships, potentially leading to errors in production or fulfillment.

However, the advent of technology has provided tools to bridge these gaps. Translation devices and software have become increasingly sophisticated, allowing real-time interpretation during negotiations or quality control discussions.

For instance, devices like the Pocketalk Translator or apps like Google Translate have become indispensable in smoothing language barriers, making it easier for brands to collaborate effectively with international partners.

2. Shipping Costs and Lead Times:

Navigating international manufacturing logistics includes managing the complexities of shipping costs and extended lead times. The distance between production facilities and the target market can significantly impact inventory management and, by extension, customer satisfaction due to longer wait times.

However, with strategic planning and the utilization of modern logistics software, brands can forecast demand more accurately and manage inventory in a way that minimizes disruptions.

Additionally, establishing partnerships with reliable logistics providers can optimize shipping routes and costs, making it possible to maintain competitive delivery times and manage expenses effectively.

3. Political and Economic Risks:

International manufacturing is susceptible to the whims of political and economic climates. Political instability, changes in trade policies, and fluctuating exchange rates can pose significant risks to the supply chain.

An example of this was seen during the US-China trade tensions, which led to increased tariffs and uncertainties for businesses relying on Chinese manufacturing. Brands must remain agile, diversify their manufacturing bases, and closely monitor geopolitical developments to mitigate these risks.

4. Weaker IP Protection:

Intellectual property (IP) protection is paramount for body care brands, especially when innovating new products. Unfortunately, IP rights enforcement can be less stringent in certain international jurisdictions, increasing the risk of counterfeit products or IP theft.

To combat this, brands should conduct thorough due diligence when selecting international manufacturing partners and consider investing in countries with stronger IP laws and enforcement mechanisms.

Additionally, registering patents and trademarks in key markets is crucial to safeguarding a brand’s intellectual assets.

Best Recommendation

You are choosing between Domestic vs. International Manufacturers. This choice is not just about balancing the books; it’s about aligning with your brand’s core values, understanding your target market, and strategically positioning yourself for long-term success.

Domestic manufacturing champions quality, speed, and ethical standards, allowing brands to capitalize on the “Made in [ZZZ]” ethos, which can significantly enhance brand loyalty and perception. On the flip side, international manufacturing unlocks cost efficiencies, scalability, and access to global innovation, allowing brands to compete effectively on price while still delivering exceptional products.

Ultimately, the decision hinges on carefully considering these pros and cons, weighed against your brand’s mission, the expectations of your audience, and your vision for the future. Whether you lean towards the bespoke, closely monitored approach of domestic production or the expansive, cost-effective strategies enabled by international partnerships, the key is to make a choice that propels your brand forward in harmony with its identity and goals.

If you’re considering becoming a brand owner or refining your manufacturing strategy, Awilke Branding is your ideal partner. Our expertise spans the intricacies of both domestic and international manufacturing landscapes, ensuring you make a decision that’s not just informed but also perfectly aligned with your brand’s aspirations.

Click the button below to contact us and take the first step towards building a body care brand that stands out and succeeds.

Innovative Trends Shaping the Future of Men’s Grooming

Innovative Trends Shaping the Future of Men’s Grooming